Noval/9-pin tubes such as your typical 12AX7 or EL84 have pins that are mounted directly through the glass envelope. Since there’s no base assembly these tubes are indexed by aligning a gap in the circular pin-out (when looking at the base of the tube it looks like there’s a missing pin) with a spacing gap in the socket contacts.

Because there’s no base assembly any stress that the pins see during installation/removal gets transferred directly to the glass envelope. This is still a very durable design but some extra care should be taken not to “wiggle” the tubes too far over when installing or removing them.

The pins on a noval/9-pin tube are quite thin and small compared to the other tubes we’re going to cover. Because of this it’s not uncommon to run into one of these tube types with a bent pin. Bent pins can occur for a variety of reasons and in most cases they can be straightened with no harm to the tube. If the culprit pin(s) are bent less than 20 degrees or so they can usually be bent back into alignment with your finger using gentle pressure. If the pin is bent more severely we suggest using a small pair of needle nose pliers to correct it. Simply start at the base of the pin and gently bring it back up-right while minimizing the leverage against the glass.

One source of bent pins is worth diving a little deeper into. In some cases if a pin is slightly bent before the tube is installed, the pin can get smooshed to the outside of the receptacles in the socket, rather than directly into the receptacle where it was designed to go. This scenario causes a few problems. First it can create a poor or intermittent contact between the pin and socket receptacle. This can lead to noise and possible tube failure. Another issue is that it creates excess side pressure on the pin which can lead to a crack forming in the glass envelope. This can crack the envelope immediately or after several heat cycles.

Lastly, this can also push the socket receptacle off center. This can bend straight pins on future tubes that end up getting installed in that socket. With all of that in mind it’s always worth inspecting the pins on the new tubes you plan to install, as well as the pins on the old tubes you’re removing.

Octal based tubes are indexed by the guide pin molded into the base assembly. Most octal bases are still molded from Bakelite and while durable, this material is somewhat brittle. The guide pin is in the center of the base between the pin terminals. The guide pin has a small timing key on it that lines up with the timing key relief molded into the tube socket. We highly recommend familiarizing yourself with the orientation of the timing key relief so that the guide pin on the tube can easily be lined up with the socket. This will reduce your risks of breaking the guide pin during installation.

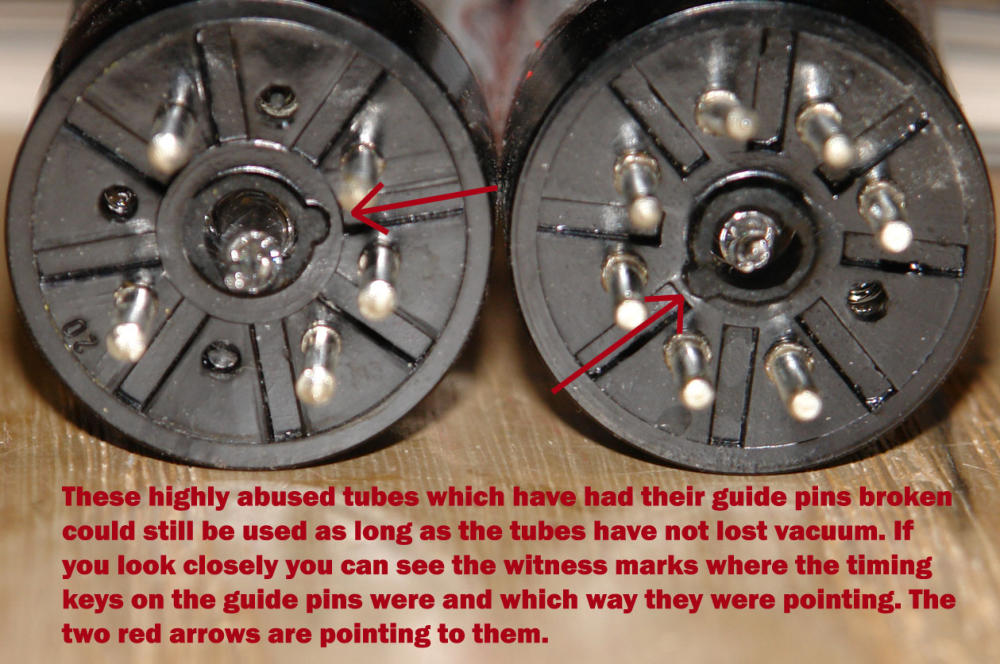

If you do encounter a broken guide pin, the tube is almost always still useable but care must be taken to manually index the tube. In most cases the broken guide pin will leave a “witness mark” where the timing key was. You can carefully lineup that witness mark with the tube socket as illustrated in the following pics:

Lastly, we do recommend always grasping octal tubes by the base during installation and removal to keep the stress off the glass envelope. In applications where this is not possible we recommend exercising a little extra care when handling the tube by the glass envelope directly.

Four Pin tubes are more commonly used in HiFi/Audio reproduction applications. From our catalog this would be the JJ 300B, 300BH, and 2A3-40. These are all filamentary triodes.

These tubes are indexed via the use of two different size pins. Of the four pins two are larger in diameter. In theory this allows the tube to only be installed in the correct orientation. However we have encountered quite a few sockets with sloppy receptacles that would allow the tube to be installed incorrectly. With that in mind make sure the tube slides in firmly but without requiring excess force. It’s always a good idea to note the orientation of the larger pins on the tubes, and the larger receptacles in the socket. This will allow you to index the tube correctly without guessing or relying on the socket interface design tolerance.

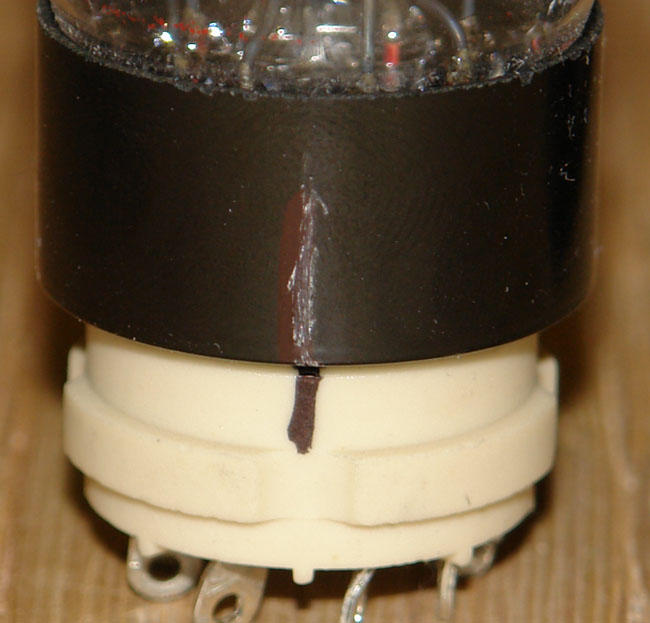

Whenever possible we recommend gripping the base of the tube during installation and removal. Excess force in any direction on the glass-to-base interface can result in damage to the tube. This is especially true on vintage tubes where the base is likely to have loosened up from the glass over time.